Fully ADA Compliant Truncated Dome Technology

Thirty years of tactile design, testing, and manufacturing insights have led up to Access® Tile’s detectable warning tiles superior product design it is today. Our truncated dome tile is the right choice for projects requiring low-cost ADA compliant tiles. Our Surface Applied tile boasts the easiest, fastest, and most environmentally conscious installation and replacement in the industry. These Surface Applied ADA tiles can be retrofitted into any existing concrete surface, using a combination of surface applied adhesive, anchors, and stainless-steel pins. All of Access® Tile’s tactile paving can be easily cut to conform to any shape, without voiding the product warranty.

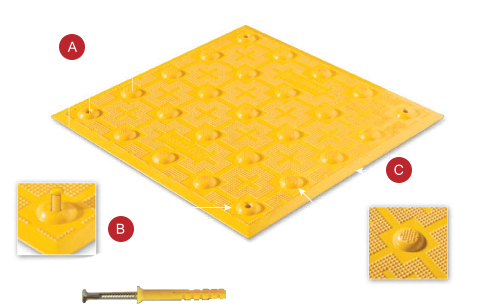

Tile geometry allows for consistent dome spacing between adjoining tiles.

High density, diamond grip™ pyramid micro texture designed for exceptional slip resistance in wet and dry conditions.

Tamper-proof, countersunk, stainless-steel Axius® fastener set flush with truncated dome surface.

Audible detectability technology engineered for sound amplification.

Textured surface to allow optimum adhesive bond.

Maximized strength load transfer design, bosses, located directly under domes transfer loads directly to substrate.

Adhesive location identified on the reverse side of tile for easy error-free installation.

Access® Tile’s Surface Applied tiles are available as multiple sizes, Radius Curve tiles, and Wayfinding tiles.

Applications for Access® Tile’s Surface Applied Tiles

All our Surface Applied detectable warning tile products are designed to be ADA compliant. The wayfinding bar tiles help guide the public safely through your space, and the truncated dome installations alert the public when the path’s edge is near a hazard. Access® Tile’s Surface Applied truncated dome tile is used worldwide for municipal curbs and pedestrian crossings, serving to warn the public when they reach an unsafe edge. The truncated domes installations can be felt comfortably through footwear, meaning our truncated dome technology is especially useful for individuals with a visual impairment. Every detectable warning paver is available many colors, including federal yellow and safety red; color contrast helps people with or without visual impairments to see the warning tiles. We have designed all of our ADA warning tiles with a unique sound reflection technology, helping those with guidance canes navigate the space safely. By tapping their guidance cane, visually impaired persons can audibly hear the difference between a walkway and ADA compliant tiles.

Common applications of Access® Tile’s Surface Applied tiles are:

- Multi-modal transit stations

- ADA curb ramps

- Accessible pedestrian crossings

- Parking areas made to be ADA compliant

- Vehicular passageways

- Safe escalator approaches

- ADA standard wheelchair ramps

- Accessible transit platforms

- Tops and bottoms of stair landings

Intelligent Design Features of our Surface Applied Tiles

Access® Tile is the industry leader in affordable detectable warning tiles. Every one of our Surface Applied tile products installs in minutes and are easily replaceable. Access® Tile is the choice of developers worldwide, for their quick installation and replacement as well as being one of the most environmentally conscious product in the industry. Multiple detectable warning pads can be anchored together using our tamper-proof stainless-steel fasteners, which maintain a flush interface with the tactile walking surface indicators.

Each tactile walking surface indicator (TWSI) is slip resistant, corrosion resistant, and abrasion resistant. All of our Surface Applied tiles have been tested rigorously, using the AASHTO HS20-44 wheel load test. All truncated domes are further tested against wear and tear to ensure the longevity of your detectable warning pad. Each ADA compliant tile is equipped with multiple fasteners to ensure maximum strength and support.

Our detectable warning tiles come in multiple colors and sizes.

Surface applied detectable warning pads can be cut on-site to conform to the most specific project needs. Access® Tile’s detectable warning mats are made to exceed all your project needs.

Available Sizes

Available Colors

FED 23594

FED 33538 / RAL 1003

FED 31350

FED 20109 / RAL 8012

FED 22144 / RAL 3016

FED 15187 / RAL 2486

FED 27925

FED 26280

FED 36118 / RAL 2486

FED 17038 / RAL 9005

Use our free radius calculator to determine the number of surface applied tiles needed for your project.

Our Surface Applied detectable warning tiles feature intelligent design and include a variety of benefits, such as:

- Environmentally conscious installation and

replacement - Adhesive location identified on the reverse side

of the tile for easy, error-free installation - Tactile bond and seal is available through all

our authorized distributors. The system is designed and tested to be both a

structural adhesive and perimeter edge sealant - Strategically placed pre-formed fastener hole

locations enhance installation integrity and provide easy installation - Interactive sizes – all tiles maintain pattern

repeat when mounted side-to-side or top-to-bottom

Installation Information for Access® Tile Surface Applied TWSI

Access® Tile’s Surface Applied ADA tiles are manufactured to be lightweight, fit in any space, extremely easy to handle, and install or replace within minutes. Our Surface Applied tile can be retrofitted into any existing concrete surface, using a combination of surface applied adhesive, anchors, and stainless-steel pins. A complete installation package is available with each order of Access® Tile’s Surface Applied truncated dome tile purchase, including a set of instructions, adhesive, and fasteners.

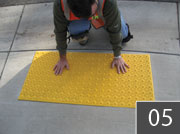

For quick reference, please see our installation and replacement instructions below:

Installation Instructions:

- Place the tile on the designated location and trace the perimeter with a thin permanent marker.

- Set the tile aside and using a 4″ diamond cup grinder, scour the concrete within the marked location and in correspondence with the location requiring adhesive as indicated in the backside of the tile.

- Clear away the dust with a leaf blower then clean the back of the tile and the concrete with a rag soaked in acetone.

- Apply surface applied adhesive to back of the tile (as indicated on the tile). The first bead should be applied thin, ½” from the perimeter edge and a second thicker bead applied 1″ inside of the first.

- Set the tile true and square to the curb ramp and press down firmly.

- While stepping down on either side of the preformed hole, drill down 3″ into concrete slab using a hammer drill and the recommended ¼” diameter carbide drill bit.

- While still applying pressure, remove the dust and any adhesive that surfaces and carefully set the supplied color-matched Axium® Fasteners with a plastic-tipped hammer. Repeat steps 6 & 7 while working across the tile from one end until all pre-formed fastener locations are completed.

- Clean the perimeter of the tile and the immediately surrounding concrete with acetone making sure to remove any adhesive that has escaped from beneath the tile. Apply and smooth sealant around the perimeter of the tile.

State and Federal Code Compliance

- 2.35″ center-to-center, in-line dome spacing

meets ADA Federal and State requirements - Truncated dome size and spacing compliant with

ADA Federal and State requirements, 0.9″ base, and 0.45″ top diameter - Fully complies with all ADA and OSHA

requirements for surface height transitions to eliminate trip hazards - Consistent dome spacing when tiles are adjoined

(side-by-side or end-to-end) - Wide in-line dome configuration facilitates a

smooth rolling transition for strollers, wheelchairs, and walkers - Integral UV stable homogeneous color throughout

truncated dome surface

All Access® Tile products fully comply with the Americans with Disabilities Act (ADA), Public Right-of-Way (PROW), and California Title 24 Requirements. For more information, please see the official Truncated Domes ADA Requirements.

ASTM & UL Tests for Surface Applied TWSI

All our detectable warning pavers undergo rigorous testing including ASTM tests, and ASTM D tests.

- Tensile Strength ASTM D638

- Flexural Strength ASTM D790

- Compressive Strength ASTM D695

- Accelerated Weathering ASTM G155

- Slip Resistance ASTM C1028

- Flame Spread Index ASTM E84

- Accelerated Aging (freeze-thaw) ASTM D1037

- Linear thermal Expansion ASTM D696-03

- Tile Bond Strength ASTM C1583