Since the 1990s, the Americans with Disabilities Act (ADA) has made tactile paving a requirement in areas where a pedestrian walkway intersects with a hazardous vehicular way. Typical applications of truncated dome tiles include transit stations, curb ramps, and pedestrian crossings. Access® Tile has the largest selection of affordable, long-lasting ADA compliant tiles, specially designed for versatility. We offer detectable warning pavers in both Surface Applied tile and Replaceable Cast in Place tile varieties. Each tactile paving tile is covered by a 5-year warranty. Access® Tile provides industry leading detectable warning products to meet all of your project requirements. Find the tactile floor tiles that are right for your project below.

Cast in Place TIles- Wet Set

Access® Tile’s Replaceable Cast in Place tiles are designed to be installed directly into fresh concrete or “wet set” and are the detectable warning products of choice for new or replaced concrete surfaces. These tactile walking surface indicators (TWSI) are produced in both wayfinding directional tiles and truncated dome configurations. Installing cast in place ADA compliant tiles takes less than 5 minutes and requires the least amount of labor of our product options. As a result, our Replaceable Cast in Place tiles boast the cheapest ADA Tile installation costs.

Our tactile floor tiles serves as a way to increase the safety and accessibility of your community, and are completely ADA compliant.

Surface Applied Tiles- Retrofit

Surface Applied truncated dome tiles are a low-cost ADA tile surface upgrade compared to removing and replacing the existing concrete transition and installing a wet set cast in place system. These detectable warning products are made to retrofit into an existing concrete surface where ADA regulation compliance is required. A combination of TBS adhesive, Axius® anchors and tamper-proof stainless-steel pins allow our Surface Applied tiles to retrofit into an existing concrete surface.

These tactile walking surface indicators (TWSI) are available in both wayfinding directional tiles and truncated dome configurations.

The retrofit ADA tile installation method makes Surface Applied tiles the ideal choice for updating an existing area. The Surface Applied tiles are also completely replaceable and can be installed or replaced in minutes, making it one of the best choices for detectable warning products.

Wayfinding Tiles- Directional Bar Tiles

Our wayfinding directional tiles have been designed to work in unison with any of Access® Tile’s detectable warning tiles. Our Wayfinding tiles create an accessible path through any hard to navigate space such as an airport or train station. When used in conjunction with truncated dome tiles which mark the decision point to change directions, start, and end of the wayfinding route this wayfinding system has proven to provide safe and efficient paths for the visually disabled in chaotic pedestrian environments. Access® Tile’s tactile Wayfinding bars are raised and can be felt underfoot through the user’s shoes and serve to guide persons of all abilities through space, especially individuals with visual impairment. These Wayfinding directional tiles are available as both Replaceable Cast in Place tile and a Surface Applied tile. These detectable warning products are versatile and can be used in a variety of applications to guide the public through your space.

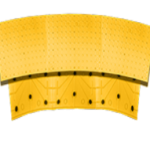

Radius Curve Tiles

A Radius Curve tile is the perfect ADA compliant tile for spaces that do not accommodate the traditional rectangle tactile paving options. This Radius ADA Tile is engineered to maximize the variance allowed by the ADA Guidelines for truncated dome spacing. Designed specifically to accommodate radius ADA compliant tile requirements at street intersections they can be installed permanently into wet set concrete, or retrofitted into existing concrete surfaces, and feature our industry-leading replaceability feature. All our truncated dome detectable warning tiles, they are incredibly easy to handle, install, or replace and come with everything you need for a long-term complaint installation for any shaped pedestrian transition. To best fit, your unique radius needs these tiles can be cut in the field to conform to the required radius applications. Common uses of our Radius Curve tiles include curbs, pedestrian crossings, and transit platforms.

Use our free Radius Curve Calculator to determine how many detectable warning surfaces you for your project.

The Power Of Intelligent Design and Precision Engineering

The result of 25 years of innovation

Tamper-proof, countersunk, stainless-steel fastener sits flush with tile surface and makes for easy replaceability in the future.

High density, diamond grip™ pyramid micro texture designed for exceptional slip resistance in wet and dry conditions.

Nylon composite, corrosion resistant anchor and stainless-steel tamper-proof fastener provide unlimited re-installation due to self-threading design.

Tile geometry maintains consistent dome spacing between adjoining Replaceable Cast in Place and Surface Applied tiles.

Hexagonal molded forms for a permanent interface between tile and anchor system. Fastener/anchor system comes pre-assembled.

Reinforced top and bottom flange determined by Finite Element Analysis (FEA) generates enhanced stiffness and structural support.

Pre-formed fastener locations enable error-free installation of our tactile floor tiles. Color-matched Axius® Fasteners with tamper-proof stainless-steel pins are supplied with tile.

Strategically placed reinforcing internal ribs determined by Finite Element Analysis (FEA) generates enhanced stiffness and structural support.

The perimeter of tile is beveled to meet ADA requirements for surface height transition.

Open end design eliminates air entrapment during installation to ensure full interface with concrete substructure.

Proven performance

The rigger of unparalleled testing procedures

Accelerated Aging, Freeze-Thaw Chamber: Extreme heat and freezing cycles test structural integrity in all climates while integral loading cylinders stress tile throughout temperature cycles to validate durability of our detectable warning products.

Taber Abrasion ASTM C 501: Measures the wear resistance of tile to ensure years of maintenance-free service.

Tensile Strength ASTM D 638: Engineering analysis calculates required strengths when exposed to externally applied forces, such as foot traffic and moving vehicles.

Gardner Abrasion ASTM D 2486: Additional wear test standard to ensure durability in high foot traffic areas of our detectable warning products.

Compressive Strength ASTM D 695: Measures compressive strength to meet AASHTO standards developed to determine the resistance of vehicular loading.

Slip Resistance ASTM C 1028: Measures slip resistance to meet ADA and OSHA standards in both wet and dry conditions.

Flexural Strength ASTM D 695: Measures flexural properties of material required to analyze the strength necessary to resist repetitive applied forces.